TEHRAN, Apr 22 - Innovations emerging from Colorado's National Renewable Energy Labs last year captured the world's imagination: Paint-on solar panels, plastic-eating bacteria, windows that double as solar collectors. But taking those proven "clean tech" ideas out of the lab and into consumer products has proved to be a complicated, years-long process.

TEHRAN, Young Journalists Club (YJC) -NREL is trying to streamline the research-to-product pipeline this year by opening up opportunities for industry and the private sector to move faster into renewable products.

TEHRAN, Young Journalists Club (YJC) -NREL is trying to streamline the research-to-product pipeline this year by opening up opportunities for industry and the private sector to move faster into renewable products.

Next month, NREL's Innovation and Entrepreneurship Center will bring researchers, companies and investors together in the lab's Industry Growth Forum, May 9-10 in Denver. The agency has also developed new contests for solar energy innovation and lithium battery recycling.

For more than 40 years, NREL has been working on big-picture projects under the U.S. Department of Energy's goals to reduce the cost to "3 cents or less per kilowatt hour" for utility-scale renewable energy by 2030.

The challenge has been getting the products to market.

Solar panels, windows

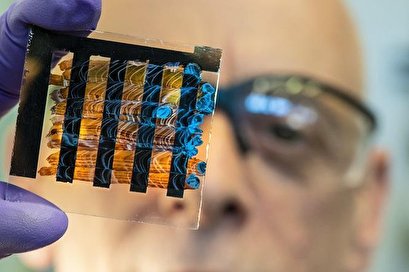

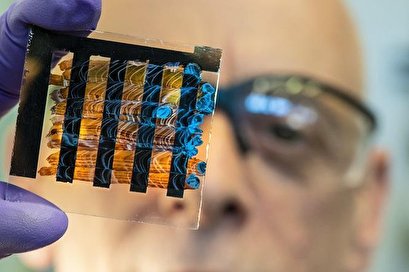

One technology that is stuck in the lab is "paintable" perovskite photovoltaic solar cells. Perovskite was named after 19th-Century Russian mineral expert Lev Perovski. It's not a mineral itself, but a mix of minerals whose molecules line up in a cube-and-diamond structure. The structure is similar to silicon, but doesn't require melting the material at thousands of degrees Celcius, said David Moore, staff scientist and self-styled "perovskite evangelist."

Because silicon requires so much heat to melt, it takes about four years of electricity generated by a silicon solar panel to replace the amount of power used to build it.

Brittle silicon crystals must be housed in rigid solar panels. But perovskite cells can layered so thinly they can be applied as a paint, or even printed on rollers as strips. Perovskite can also be colored and used for LEDs and lasers. Moore believes the material is "probably the future of most optical electronics."

"Imagine PV everywhere -- PV cars, PV backpacks," Moore told UPI. His vision is "ubiquitous electricity that's almost free."

Consumers are hungry for renewable energy products in their homes. When NREL scientist Lance Wheeler discovered technology for a perovskite glass switchable solar window that absorbs heat in the winter and turns clear in warm weather, NREL's phones lit up with people asking how to order them, Moore said.

But the industry just isn't there yet.

"There's a big gap between 2 square inches of material to something that can be installed on a house," Moore said.

Costly development

Part of the problem for clean-tech companies is a perilous funding journey across the financial commercialization "valley of death," Moore said. Funds are plentiful in the research and development stage (often subsidized by universities or the government) and then again at the other end of the timeline, when consumers buy the products. But money dips dangerously low when companies are developing the products.

Source:upi

TEHRAN,

TEHRAN,